Designing components for a super car means thinking big, delivering exceptional performance, and executing a flawless design. Learn how Hutchinson worked with Protolabs to injection mould a battery pack cooling system in just 5 weeks for an Italian electric supercar.

At A Glance

Challenge

Injection moulding 210 parts in 5 weeks for the battery pack cooling system for a fully electric super sports car prototype

Solution

Hutchinson relied on Protolabs to obtain three different components within the required time and with the prescribed quality. The speed of interaction between Hutchinson and Protolabs, combined with experience in the automotive sector, allowed for the production of 210 parts in less than 5 weeks from the first contact.

Outcome

The iteration speed of Protolabs and Hutchinson led to perfect parts being delivered on time, ready to be tested and installed on the supercar prototype, reducing validation and testing times.

In June 2023, 138,937 new cars were registered in Italy. Of these, just under 10% were electric cars: 7,539 plug-in hybrids and 6,159 fully electric vehicles. Adding the remarkable figure of 48,937 new electric hybrids, electric and hybrid cars together accounted for almost 45% of new registrations.

Hutchinson, a Total Group subsidiary, is a French multinational with 38,000 employees across more than 100 industrial sites in 25 countries, specialising in designing and manufacturing polymer-based products and systems for fluid management. Located in Rivoli, near Turin, is the global centre of competence for automotive fuel systems, typically for diesel or gasoline vehicles. However, in electric cars, such a system is non-existent. Instead, a similarly crucial component for the proper functioning of electric cars is the battery pack temperature stabilisation system, a critical node for vehicle safety.

In 2025, Italy will introduce a fully electric supercar, and work on prototype development has already begun, thanks to the collaboration between Protolabs and Hutchinson.

Designing a supercar means thinking big, and Engineer Valter Mondini, Project Manager, understands that no detail can be left to chance in a project of such significance. Hutchinson was brought in to find the best solution for cooling the battery pack. For a car to be defined as a supercar, it must deliver exceptional performance in speed and range, the latter being determined by a battery pack as extensive as possible while minimising space for other elements.

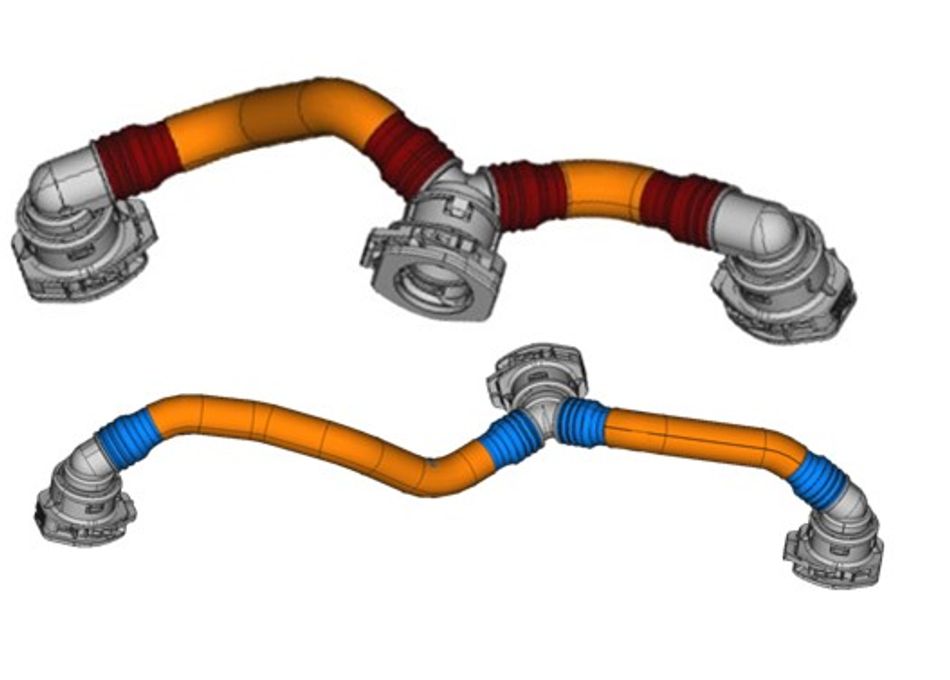

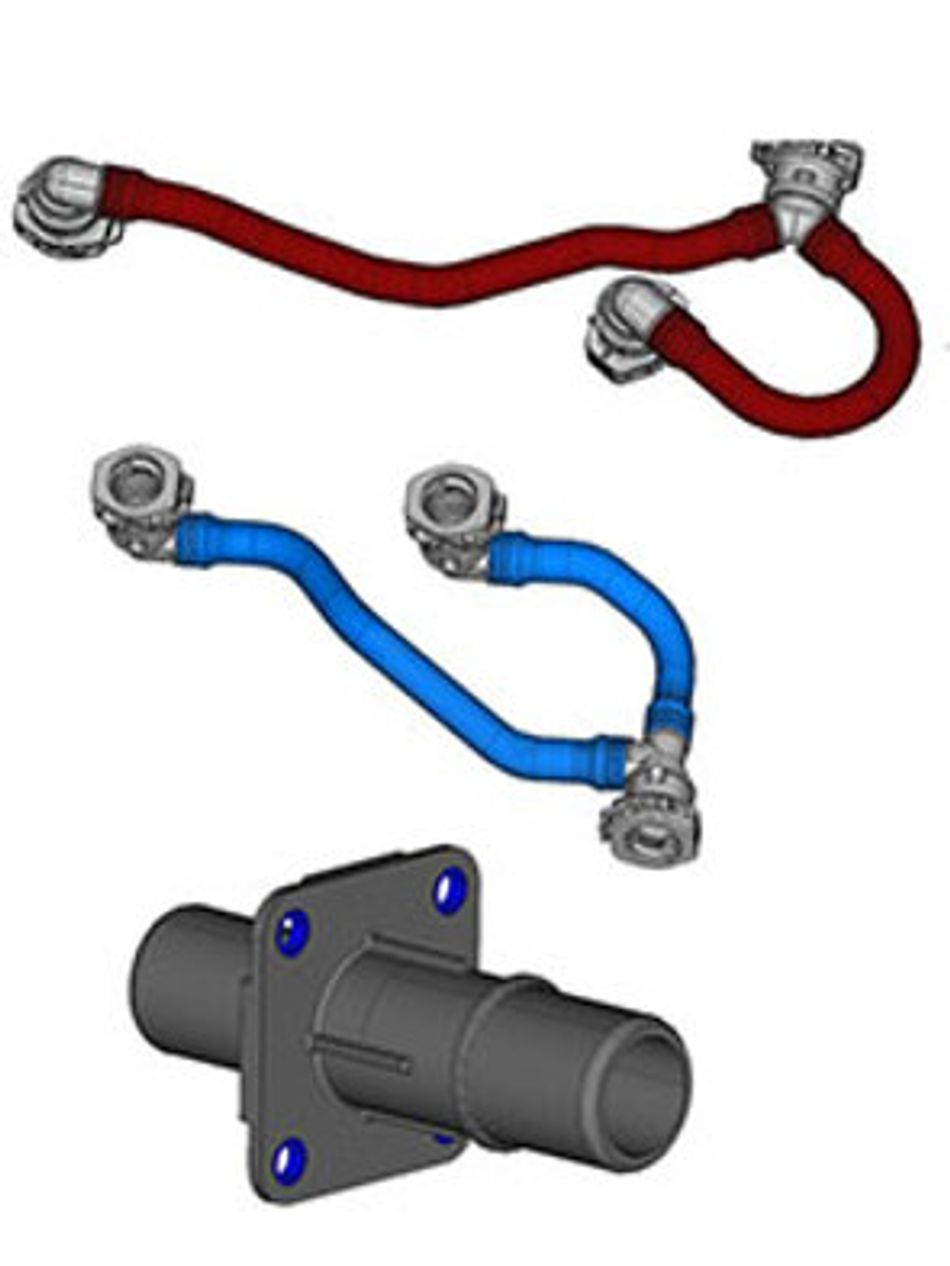

The main technological challenge was minimising the space the hydraulic system used to cool the battery pack took. This involved replacing the material used to make the tubes. Initially, the tubes were made of rubber that contained water and glycol, but Protolabs replaced the material with extruded plastic, ensuring the same mechanical performance. Each piece had to be flawless to guarantee a seal of up to 4 Bar. It was crucial to avoid any moulding imperfections, such as burrs, as they could mark the tube during the cold fitting phase and compromise the hydraulic system's seal.

"Protolabs is among Hutchinson's accredited suppliers and collaborates on projects where the speed of iteration and the quality of the products obtained are unparalleled. They accepted the challenge. The timelines were extremely tight: we needed to produce four different injection-moulded components in the specified material, with particularly tight tolerances given the importance of the battery cooling hydraulic system. Given the project's significance," explains Engineer Mondini of Hutchinson, we could not afford any mistakes.

"Protolabs is among Hutchinson's accredited suppliers and collaborates on projects where the speed of iteration and the quality of the products obtained are unparalleled. They accepted the challenge."

V. Mondini, Project Manager & Engineer at Hutchinson

"Upon receiving the initial request from Hutchinson," explains Stefano Mosca, Senior Account Manager at Protolabs in Italy, "we immediately involved our injection moulding centre of excellence in Eschenlohe, which is particularly accustomed to responding to requests from the automotive sector. We were already familiar with the sector's required standards and knew that when we are involved in a project, it is primarily for the speed and quality assurance of the parts we produce. In 5 weeks, we validated the project, produced the moulds, chose the filler percentage of both Nylon and PPS together with the customer, injected moulded the parts, and shipped them."

The project is a fine example of international collaboration. The development project for these components was undertaken in Italy, developed in France, produced in Germany, tested in Italy, and a portion of the parts was shipped from Protolabs to Poland to be mounted on some prototypes— a fitting example of how an international supercar, which will be sold worldwide, is born.

About Hutchinson:

Hutchinson designs and manufactures smart solutions for a world on the move and contributes to future mobility on land, in the air and at sea. With expertise in fluid transfer, sealing, anti-vibration systems and materials & structures, Hutchinson is a global leader in developing innovative solutions for sustainable mobility.

To find out more, visit the Hutchinson website.